Table of Contents

ToggleDid you know that a smart sales and operations planning process can easily boost your fill rate by 8% without spending an extra dollar? Of course, every business plans their operations. However, not every business understands how to do this right. This is where the concept of S&OP comes in—a structured approach that transforms scattered planning efforts into cohesive results that deliver measurable and clear business results.

At its core, sales and operations planning connects demand planning with operational plans. It creates a certain level of business harmony. When marketing, sales, production, and finance teams align their objectives, companies can respond quickly to market changes while maintaining healthy margins. Such a cross-functional collaboration process ensures inventory levels match actual customer needs. However, let’s take it one step at a time.

What Is Sales and Operations Planning (S&OP)?

Let’s begin with a clear definition. Sales and operations planning is a collaborative business process that aligns demand plans with production capacity to ensure operational efficiency at all levels. It is a key element of strategic management for companies across various industries. S&OP connects sales forecasts, inventory requirements, and financial goals into a unified plan that supports broader business objectives. It also creates a structured framework where cross-functional teams work together to balance customer needs with company capabilities.

When implemented effectively, this process improves forecast accuracy, reduces excess inventory, enhances cash flow, and helps organizations respond quickly to market changes (all while maintaining profitability). This process may seem complex at first glance; however, the truth is that in 2025, tools for advanced analytics and artificial intelligence have made implementing a robust sales and operations planning process easier and more accessible than ever before.

Main Benefits of Sales and Operations Planning

Implementing a robust S&OP process delivers significant advantages for businesses seeking to improve their operations:

Enhanced Transparency and Control

S&OP eliminates departmental silos by creating a unified information system where all data flows together. This transparency helps leadership spot potential issues before they become problems and enables comprehensive oversight of the entire supply chain process.

Improved Forecast Accuracy

By aligning demand planning with production capacity, companies implementing S&OP can boost their fill rate by 8% without additional investment. This improved accuracy reduces both stockouts and excess inventory situations that hurt customer satisfaction and eventually profitability.

Significant Cost Reduction

Effective sales and operations planning maintains service levels while substantially cutting inventory costs. Real-world examples show savings of up to $20 million by optimizing inventory deployment and reducing costly expedited shipments.

Greater Business Agility

Modern S&OP processes enable organizations to adapt to changing market conditions really quickly. Such agility is critical in today’s volatile business environment, as it allows companies to respond promptly to issues such as supply disruptions, demand fluctuations, and competitive pressures.

Cross-Functional Collaboration

S&OP creates a structured framework where teams from marketing, sales, operations, and finance align their objectives and set shared goals. This team goal-setting reduces conflicts between departments and ensures everyone works toward common business objectives.

Real-Time Decision Making

Today’s S&OP solutions leverage advanced analytics and AI to provide actionable insights. Modern analytics is based on current data rather than historical information. This shift from reactive to proactive management helps businesses anticipate challenges, not just wait idly.

Core Components of the S&OP Process

The sales and operations planning integrates various business functions to create alignment between demand and supply. Below are the four essential components that form the foundation of any effective S&OP framework.

Demand Planning

This initial phase involves forecasting future sales based on historical and current data, market trends, and customer insights. We have previously written a dedicated article on how to create a sales plan that covers this component in detail. Effective demand planning requires sales planning tools that can analyze patterns as well as predict future requirements and cohesive cross-team work.

Supply Planning

Once demand is forecasted, the supply planning stage determines how to meet that demand. It is typically done through production scheduling, inventory management, and resource allocation. Supply planning ensures operational plans align with anticipated market needs.

Financial Integration

At this stage, businesses reconcile demand and supply plans with financial goals and budgetary constraints. This step ensures that operational decisions support profitability targets and capital efficiency objectives.

Executive Review

Finally, this component involves senior leadership reviewing and approving the integrated plan. This stage encompasses a wide range of considerations, including building risk assessment matrices, checking strategic alignment, and performance monitoring—completing the planning cycle before it begins again.

Who Is Involved in the S&OP Process?

Effective sales operations planning requires participation from stakeholders representing various departments. For instance, senior management provides strategic direction while functional teams contribute specialized expertise and execute the plans. This collaboration ensures all aspects of the business are aligned toward common objectives.

Key participants typically include:

- Supply chain leader: Orchestrates the overall process and resolves conflicts between functions;

- Marketing teams: Contribute market insights and promotional plans that impact demand;

- Operation teams: Determine production capabilities and resource requirements;

- Sales leadership: Provides revenue forecasts and customer insights;

- Finance representatives: Ensure plans support financial goals and budget constraints;

- Senior management: Provides final approval and ensures alignment with business strategy.

Step-by-Step S&OP Process Guide

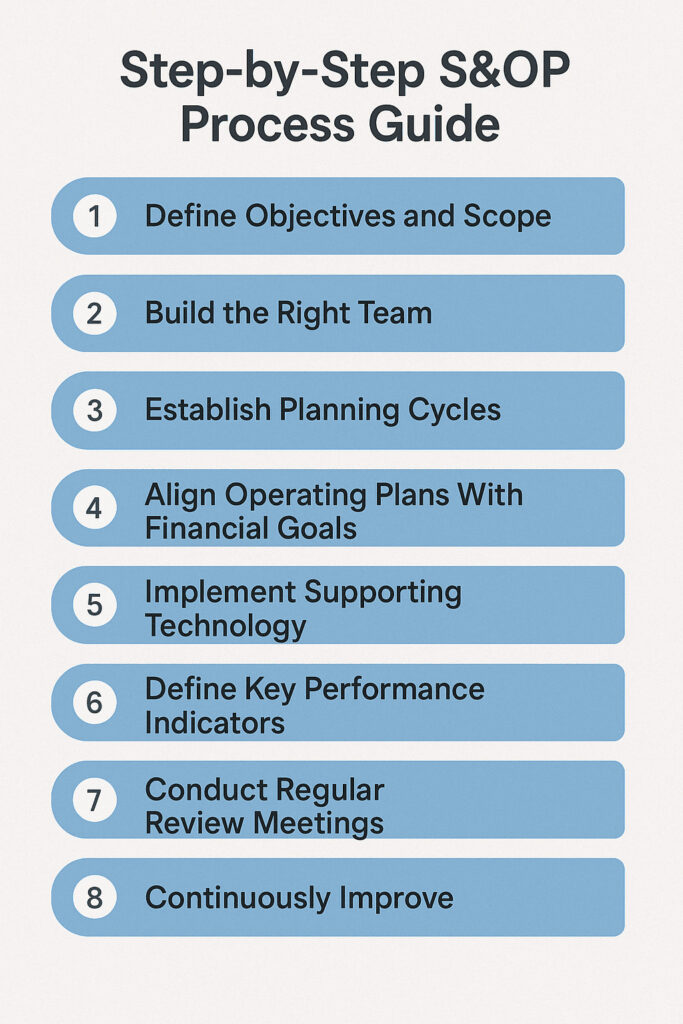

Implementing sales and operations planning requires a structured approach to align business functions and create a unified planning framework:

Step 1: Define Objectives and Scope

Establish what you want to achieve with your S&OP implementation, including financial plan integration and which products or business units to include.

Step 2: Build the Right Team

Form a cross-functional team with representatives consisting of the specialists mentioned in the section above.

Step 3: Establish Planning Cycles

Create a regular cadence for S&OP meetings (typically monthly) with a defined schedule for data collection, analysis, and review.

Step 4: Align Operating Plans With Financial Goals

Ensure production and inventory plans support both operational requirements and financial targets of your business.

Step 5: Implement Supporting Technology

Deploy appropriate sales and operation planning software and practices to facilitate data collection, analysis, and collaboration. (We will return to such software a bit later)

Step 6: Define Key Performance Indicators

Develop metrics to measure the effectiveness of your S&OP process, including forecast accuracy, inventory levels, and service rates.

Step 7: Conduct Regular Review Meetings

Hold structured meetings where all stakeholders review performance, resolve conflicts, and make integrated decisions.

Step 8: Continuously Improve

Regularly assess and refine your sales and operations planning workflow based on outcomes and changing business needs.

Common Challenges in S&OP Implementation

According to a Forbes article on this subject, implementing S&OP planning faces several common challenges that can eventually undermine financial performance. Here are some ot the difficulties mentioned by them:

- Organizations often struggle with siloed departments that make informed decisions difficult;

- Marketing, sales, and operations teams work with disconnected data in separate systems;

- Businesses frequently lack real-time visibility across their supply chain, resulting in poor inventory management and reactive rather than proactive planning;

- Without unified S&OP systems that integrate all business functions, companies miss opportunities to optimize their operations and struggle to respond quickly to changing market conditions.

However, this is not a condemnation. Let’s see what businesses can do to mitigate and overcome these challenges.

S&OP Best Practices for Maximum Efficiency

| Challenge | Solution Strategy |

|---|---|

| Siloed departments with disconnected data | Implement integrated data systems that provide a single source of truth across all functions |

| Lack of real-time visibility | Deploy advanced analytics platforms with real-time dashboards and alerts |

| Reactive rather than proactive approach | Incorporate predictive analytics and scenario planning into your S&OP pipeline |

| Poor inventory management | Use inventory optimization tools that balance service levels with carrying costs |

| Difficulty responding to market changes | Establish more frequent S&OP review cycles and exception-based planning; use AI to predict market trends and changes better |

| Conflicting departmental objectives | Create shared KPIs that align all departments toward common business goals |

| Inadequate executive support | Demonstrate the ROI of effective sales and operation planning with clear financial impact metrics |

| Poor forecast accuracy | It’s 2025: Implement machine learning algorithms that continuously improve prediction quality |

| Manual, time-consuming processes | Automate data collection and reporting to free resources for analysis |

| Lack of S&OP process standardization | Develop clear procedures and governance for consistency across business units |

How Technology Powers S&OP

Modern technology has revolutionized sales and operations planning by introducing AI-powered solutions that dramatically improve forecast accuracy and decision-making capabilities. According to the industry research by Forbes, companies leveraging advanced S&OP technology report up to 31% revenue growth, 46% inventory reduction, and 39% improvement in customer satisfaction. Today’s integrated platforms connect previously siloed departments and provide real-time visibility across the entire supply chain.

Key technological advancements in sales and operations planning in 2025:

- AI-powered demand forecasting with predictive analytics;

- Machine learning algorithms that continuously improve forecast accuracy;

- Real-time data integration across all business functions;

- Automated scenario planning for risk assessment;

- Advanced analytics dashboards for performance monitoring;

- Cloud-based collaboration tools for cross-functional planning;

- Digital twins that model supply chain networks in detail;

- Predictive maintenance capabilities to prevent disruptions.

The Growing Role of AI in S&OP: How to Choose the Right Tools

AI in B2B sales has fundamentally transformed how companies approach sales and operations planning. In 2025, not using AI for your S&OP process is like operating without computers in the 2000s—technically possible, but creating a massive competitive disadvantage. Modern AI solutions can process vast amounts of historical and real-time data to detect patterns beyond human capability, reducing forecast errors by 30-50% while identifying inventory optimization opportunities.

Although numerous planning tools offer AI capabilities for specific S&OP components, most operate as disconnected solutions requiring manual data integration. That’s why we developed an innovative platform that completely changes the approach to S&OP planning.

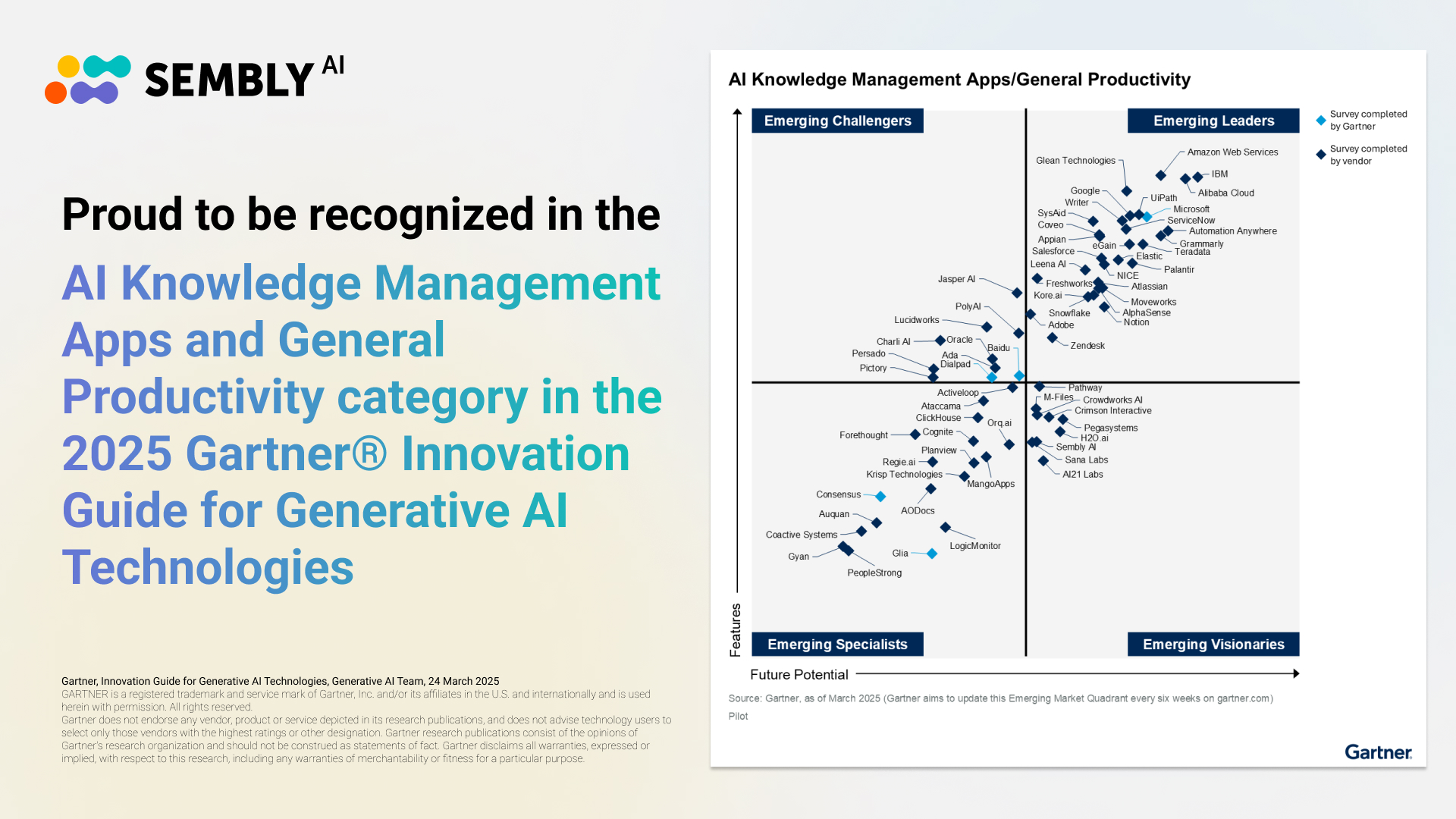

Meet Sembly, an AI-Tool You Will Certainly Benefit From

Sembly AI completely revolutionizes meeting productivity with advanced transcription and summarization capabilities useful for your sales and operations planning meetings. The platform automatically captures every decision, action item, and insight discussed in your S&OP sessions, ensuring nothing falls through the cracks. With multi-language support and seamless integration with your favorite CRMs and project management software, Sembly transforms scattered meeting data into searchable, actionable intelligence.

Semblian 2.0, an add-on to the original product, takes this foundation to the next level with its Augmented Worker Intelligence. This powerful AI assistant generates comprehensive artifacts like sales proposals, contract negotiation summaries, and sales activity plans with just a single click. The system can easily analyze multiple meetings at once through multi-meeting chats, identifying patterns across customer interactions and providing contextual insights tailored to your role and business needs.

When using Sembly for sales and operations planning specifically, S&OP teams get immediate value through automated documentation and insight extraction. The platform records all planning meetings and identifies key discussions about demand forecasts and production schedules. Sales teams can generate pipeline reports that align with operational constraints. Supply chain leaders can track implementation progress without traditional note-taking methods. Sembly eliminates administrative burden while highlighting risk and opportunities that might otherwise remain buried in meeting recordings.

Ready to start your sales and operations planning with AI? Try Sembly today to capture every important insight, automate documentation, and foster a culture of data-driven decisions that drive real business growth. Visit Sembly.ai to start your free trial.

FAQs

What is S&OP’s meaning?

S&OP’s meaning is sales and operations planning—a business process that aligns demand forecasting with production capacity to ensure operational efficiency and financial performance.

How does S&OP planning improve business performance?

Sales & operations planning improves performance by reducing inventory costs, enhancing forecast accuracy, preventing stockouts, and aligning cross-functional teams around shared goals in metrics.

Who should participate in the S&OP meetings?

The sales operations planning process should include representatives from sales, marketing, supply chain, operations, finance, and senior management in order to ensure all perspectives are considered.

How often should sales forecasts be aligned with production capacity?

Sales & operations planning forecasts should be aligned with production capacity at least monthly. It allows you to ensure operational efficiency, prevent stockouts, and balance inventory costs with customer service levels.

Introducing Semblian 2.0

- ✦ Multi-Meeting Chats

- ✦ AI Insights

- ✦ AI Artifacts